Product description

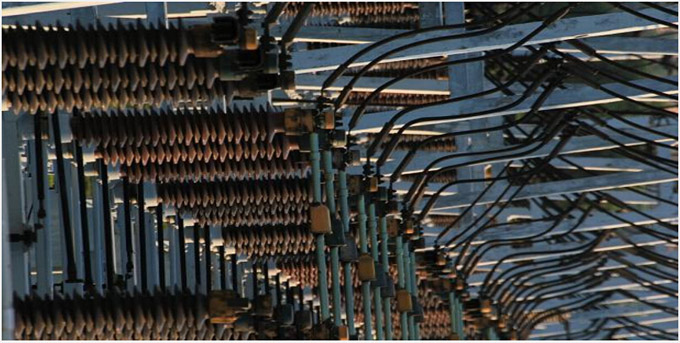

ZS-1091 thermostable ceramic insulating coating ( temperature resistance 1700 ℃ ) when applied on the object surface , it will form a layer of ceramic coat which has relative high volume resistivity and can withstand high electric field . The coat has high mechanical strength and good chemical stability . Meanwhile it is anti-aging, waterproof , anti chemical corrosion with high thermal conductivity . To conclude it is a kind of multifunctional coating which can protect your device and your personal safety .

Working principle

The film former of ZS-1091 (1700℃) coating is water-based inorganic silicate solution. Therefore, the coating can resist temperature up to 1700℃ and can be applied onto any materials with a good adhesion. The coating can resist high temperature, meanwhile it can insulate electrical current and avoid the occurrence of corona discharge.

A ceramic coat, which has a high volume resistivity and can withstand a strong electric field without being breakdown, will be formed on the surface of the coated object. The coat has a high mechanical strength and good chemical stability, with the performance of anti-aging, waterproof and chemical corrosion resistance.

The coating also has a high thermal conductivity, which means it can release heat easily, meanwhile it has resistance ability against mechanical shock and thermal shock. Thus such coating can work constantly under certain working condition (600 ℃).In addition, the special film forming solution makes it easier for application. According to different condition of voltage and electric current, a certain thickness of single layer can work perfectly.

Such coating selects special solution made by organic - inorganic polymer as binder, compact inorganic crystalloid material like Aluminium Oxide and Silicon Oxide as filler, ceramic paticle as film former. Strictly control the ratio of raw material and avoid the existance of alkali metal and alkali-earth metal ions. Reduce the content of glass phase and reduce the electric conductivity raised by glass phase. Control the addition of valence changeable ions like iron and cobalt in case of free ion and electron hole. Strictly control the temperature and atmosphere in case of electron and hole caused by redox reaction, avoiding crystal defect caused by lattice transformation. It can be applied onto surface of any material, solidifying in normal temperature. Solidification time is above 24 hours.

Parameters

| Item |

Testing Standard |

Result |

State in Container |

GB 9755-2001 5.3 |

No concretion

No flocculation

No precipitate |

| Flexibility |

GB/T1721-83 |

≤4mm |

| Color |

GB/T 1722-1992 |

Light Green

|

| Solid Content |

60% TU-4 Cup Viscometer |

over 60s |

| Adhesive Force |

GB/T 9286-1998 |

Grade I |

Calorific Value Coefficient

|

Tested in Room Temperature |

Thermal Conductivity : 60W/m.K

Heat Capacity : 1800J /(kg·℃) |

| Coefficient of Linear Expansion |

GJB 332A-2004 |

18*10-6/℃ |

| Coating Hardness |

GB/T 6739-2006 |

7 H |

| Curing Time |

GB/T 6753.2-1986 |

Tack-Free 2 h

Cure 24 h |

| Bonding Strength |

GB/T16777-2008 |

8 Mpa

|

| Bending Strength |

GB/T1832-1993 |

≤4Mpa |

Tensile Strength

(high temperature) |

GB/T 16777-2008 |

8 Mpa |

| Thermal Conductivity |

GB/T 10294-2008 |

0.05W/m.k |