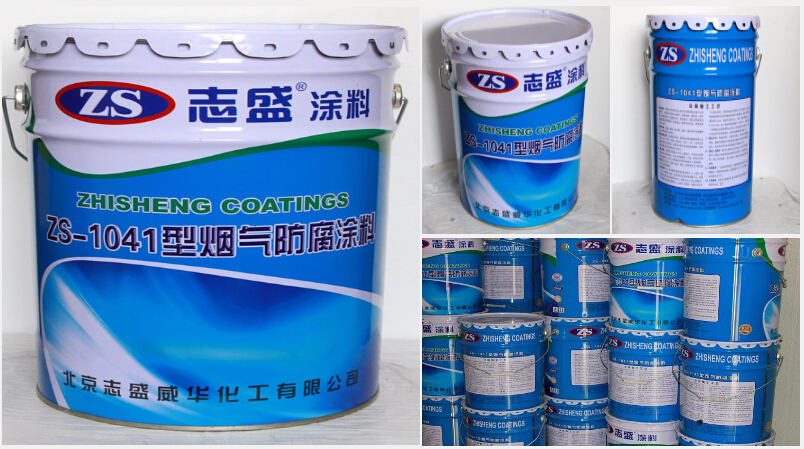

Product Description

ZS-1041 Chimney and Flue Gas Duct Inner Wall Anti-Corrosion Coating adopts modified resin as film former. The main chain of resin is inorganic silicon polymer, grafted by organic polymer, forming network-structured polymer that contains advantages of both organic and inorganic materials. Such coating contains following fillers: nano-silicon powder, silicon carbide, fine-grained alumina, graphite, titanium oxide, ceramic cenosphere, zirconia powder. The cured coating has low surface energy, high hardness, high bonding force with substrate and excellent anti-corrosion property.

Working Principle

ZS-1041 Flue Gas Anti-Corrosion adopts modified resin as film former. The main chain of resin is inorganic polymer that contains silicon, grafted by organic polymer in high temperature, forming network-structured polymer that contains advantage of both organic and inorganic materials. It has good film forming ability and adhesive force. The coating layer is sooth, high-temperature resistant, highly compacted so it can reduce the dielectric loss factor. The solid state filler was made into wear-resistant ceramic functional filler in sealed and high temperature environment. It enhance the hardness and wear resistant ability of coating. Meanwhile it has anti-corrosion, thermostable, impact resistant and ductility.

Parameters

| Item |

Result |

Test Standard |

| Appearance |

Viscous Liquid |

By Naked Eyes |

| Viscosity |

Lower than 60s |

GB/T1723-79 |

| Density |

1.8g/cm3 |

Density Tester

|

| Curing Time |

Summer ≤2h Winter ≤8h |

Change with ambient temp |

Workability |

Wet Film 120μm

No sagging |

TB/T2932-98

|

| Item |

Testing Standard |

Result |

State in Container |

GB 9755-2001 5.3 |

No concretion

No flocculation

No precipitate |

| Coating Appearance |

GB/T 1721-2008 |

No Cratering |

| Color |

GB/T 1722-1992 |

Black

|

| Solid Content |

ISO 3233:1998 |

≥70% |

| Adhesive Force |

GB/T 9286-1998 |

Grade I

|

| Curing Time |

GB/T 6753.2-1986 |

Tack-Free 2h Curing Time 24h |

| Flexibility |

GB/T1731-93 |

2 mm |

| Coating Hardness |

GB/T 6739-2006 |

5 H |

| Bonding Strength |

GB/T16777-2008 |

8 Mpa |

Tensile Strength

(high temperature) |

GB/T 16777-2008 |

8 Mpa |

Performance test

| Acid Resistant Test |

GB/T 9274-1988 |

(10% H2SO4 over 60℃)

200 days no change |

| Alkali Resistant Test |

GB/T 9274-1988 |

(10%NaOH over 60℃)

200 days no change |

| Salt Mist Resistant Test |

GB/T 1771-91 |

15% NaCl 300h no change |

| High Temperature Test |

GB/T 2423.2 |

750℃ |

Package

20 kg / iron drum

Application

All kinds of flue, chimney, desulfuration device, kiln lining etc. where there is corrosion caused by acid, alkali, flue gas and dust.