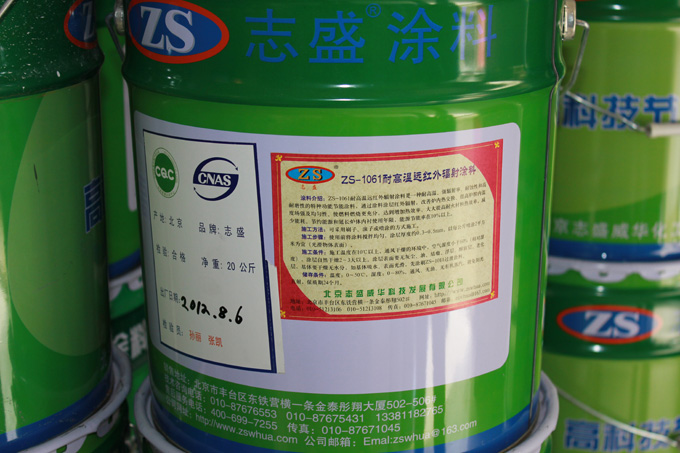

Product description

Components and Features

ZS-1061 Thermostable Far-Infrared Radiation Coating adapts Inorganic Silicate Compound System as film former, adding transition-metal oxide, zirconia, yttrium oxide as filler. The cured coating has following features:

- Stable and relatively high infrared emissivity

- High Temperature Resistant

- Anti-Corrosion

- High Hardness

- Wear-Resistant

Working principle

ZS-1061 Thermostable Far-Infrared Radiation Coating contains transition-metal oxide, zirconia and silicate refractory. All of these components were mixed in high temperature to form solid solution. Such procedure can increase impurity level and infrared emissivity, meanwhile it can keep the heat resistant ability, hardness, anti corrosion property and wear resistant ability. All material above can enhance the overall strength and compactness of coating.The introduction of zirconia can boost the activity of reactant, it also helps to stabilize the coating structure.

Parameters

| Item |

Testing Standard |

Result |

State in Container |

GB 9755-2001 5.3 |

No concretion

No flocculation

No precipitate |

| Color |

GB/T 1722-1992 |

Green |

| Adhesive Force |

GB/T 9286-1998 |

1 |

| Pliability |

GB/T1731-93 |

4mm |

| Coating Hardness |

GB/T 6739-2006 |

5H |

| Infrared Emissivity |

GJB 5023.2-2003 |

0.95 |

Performance test

| Salt Mist Test (24h) |

HG/T 4565-2013 |

No foaming, No Falling

No Crack,No Rust |

| Anti-Oxidation Test |

HG/T 4565-2013 |

No Corrosion

No obvious oxide color |

| High Temperature Test |

GB/T 2423.2 |

1800℃ |

Package

Application

ZS-1061 Thermostable Far-Infrared Radiation Coating can be used in following devices:

- kiln

- firepot

- boiler lining

- coal furnace

- high-temperature furnace

- high temperature electric furnace